Stupite u kontakt s nama

Telefon

Austrija

13.08.2018

PEM RANGLE fasteners The clever solution for many different fields of application

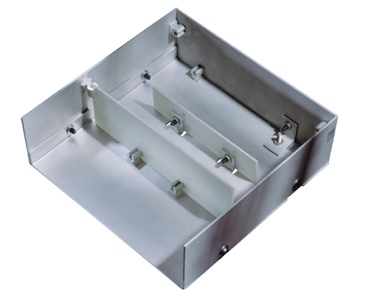

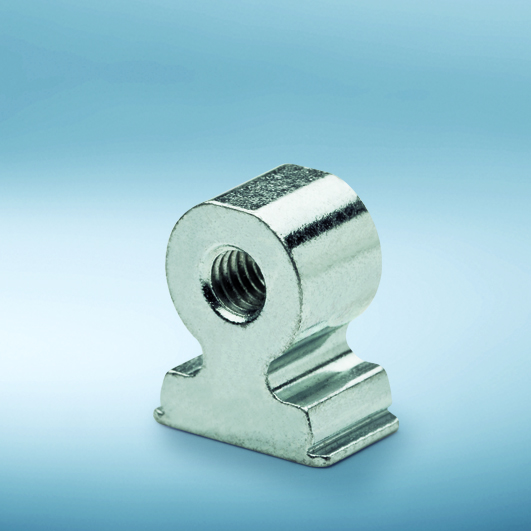

The international fastening expert KVT-Fastening offers a comprehensive range of the proven PEM® self-clinching fasteners. In the well-known range there is to be found a clever solution for right-angle connection of thin metal sheets from 1 mm in thickness: the PEM® angle bracket R’ANGLE (right angle). Its great advantage: instead of compromising with separate metal angles, bevelling or free punching, the R’ANGLE is inserted rigidly and flush into rectangular punched holes. In a second step, end plates, PC boards, dividers and much else can be reliably fastened. There are two versions of the R’ANGLE available for this: type RAS is already threaded and only needs to be fitted with an M3 or M4 bolt. Type RAA by contrast is designed for use with M3 and M4 self-tapping screws. The PEM® R’ANGLE angle bracket is in demand in every place where permanently-secure fastenings are specified – among other places, in instrument manufacture, in electronics cabinets, in computers, in household appliances and in the telecommunications industry.

In countless industrial fields today, thin metal sheets are used as standard. PEM® R’ANGLE are invariably used whenever components have to be mounted at right angles to one another. "As self-clinching fasteners they guarantee absolutely reliable fastening. In addition, they are practical to install and thus they save time and money as well", as Matthias Schorer, Product Manager PEM® at KVT-Fastening says. R’ANGLE is installed in a punched hole in the workpiece. In this area, the fastener displaces the base material. Thanks to its special shape, the R’ANGLE angle bracket thus becomes a piece of the base material. In the next step, all the components which require fastening at a right-angle are simply screwed into the workpiece using either predrilled holes or self-tapping screws. Schorer: "This principle makes assembly considerable easier, since for example it is no longer necessary to cut all the threads in advance. For another thing, this way there are no filings produced which again keeps the work area much cleaner and this in turn makes for a safer working environment“. Furthermore, using self-tapping screws with the type RAA leads to the highest possible degree of resistance to loss of angle bracket and screws. Since neither bevelling nor separate brackets are now needed, the principle also scores by achieving lower material costs.

The PEM® R’ANGLE angle brackets are available as type RAS (sintered steel) for M3 and M4 bolts and for sheet hardness up to HRB 60; as type RAA (aluminium) for self-tapping screws they are for use in materials with hardness of up to HRB 45.